Maintenance of polycrystalline diamond wire drawing dies

Effective maintenance and repair of polycrystalline wire drawing dies molds is very important for reducing costs.

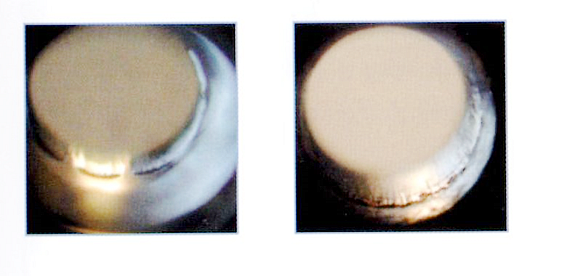

Due to the vibration of the wire rod, some slight annular wear occurs in the contact area of the pcd wire drawing die first, and then continues to expand towards the sizing area, resulting in a serious decline in the surface quality of the wire rod and an expansion in the wire rod size. Moreover, severe wear can cause transverse or longitudinal cracks in the mold, leading to premature scrapping of the mold.

Maintenance of polycrystalline diamond wire drawing dies

Effective maintenance and repair of polycrystalline wire drawing dies molds is very important for reducing costs.

Due to the vibration of the wire rod, some slight annular wear occurs in the contact area of the pcd wire drawing die first, and then continues to expand towards the sizing area, resulting in a serious decline in the surface quality of the wire rod and an expansion in the wire rod size. Moreover, severe wear can cause transverse or longitudinal cracks in the mold, leading to premature scrapping of the mold.

Previous: Wire drawing dies of different materials

Next: Causes of bursting of Tungsten Steel alloy Wire Drawing Die