Why is the diamond wire drawing dies scrapped after one use

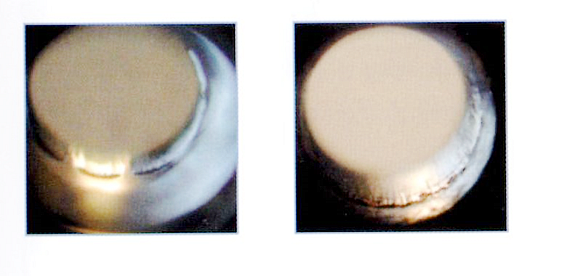

During the long-term use of wire drawing dies,the mold wall is subjected to strong friction and erosion from metal wires,which inevitably leads to wear and tear.The most common phenomenon is the appearance of circular grooves (dents) at the entrance of the wire in the work area.The appearance of circular grooves in various wire drawing dies exacerbates the wear of the dies holes,as small particles of dies core material that have peeled off due to looseness on the circular grooves are brought into the working and sizing areas of the dies holes by metal wire dies,playing the role of abrasives.The wire that enter the die holes, like grinding needles,exacerbate the wear of the drawing dies holes.

If not replaced in a timely manner for repair,the ring groove will continue to accelerate and expand,making repair more difficult,and there may even be cracks in the deeper part of the ring groove,causing the mold to completely collapse and scrap.It is very cost-effective to establish a set of standardized standards,strengthen daily maintenance,and regularly inspect the die stamping plate.Once there is any slight wear on the wire dies,timely polishing will take less time to restore the die to its original polished state,and there will be no significant changes in the hole size of the drawing dies.

Why is the diamond wire drawing dies scrapped after one use

During the long-term use of wire drawing dies,the mold wall is subjected to strong friction and erosion from metal wires,which inevitably leads to wear and tear.The most common phenomenon is the appearance of circular grooves (dents) at the entrance of the wire in the work area.The appearance of circular grooves in various wire drawing dies exacerbates the wear of the dies holes,as small particles of dies core material that have peeled off due to looseness on the circular grooves are brought into the working and sizing areas of the dies holes by metal wire dies,playing the role of abrasives.The wire that enter the die holes, like grinding needles,exacerbate the wear of the drawing dies holes.

If not replaced in a timely manner for repair,the ring groove will continue to accelerate and expand,making repair more difficult,and there may even be cracks in the deeper part of the ring groove,causing the mold to completely collapse and scrap.It is very cost-effective to establish a set of standardized standards,strengthen daily maintenance,and regularly inspect the die stamping plate.Once there is any slight wear on the wire dies,timely polishing will take less time to restore the die to its original polished state,and there will be no significant changes in the hole size of the drawing dies.

If not replaced in a timely manner for repair,the ring groove will continue to accelerate and expand,making repair more difficult,and there may even be cracks in the deeper part of the ring groove,causing the mold to completely collapse and scrap.It is very cost-effective to establish a set of standardized standards,strengthen daily maintenance,and regularly inspect the die stamping plate.Once there is any slight wear on the wire dies,timely polishing will take less time to restore the die to its original polished state,and there will be no significant changes in the hole size of the drawing dies.

Previous: Reasons for wear of wire drawing dies

Next: Innovation of Diamond Wire Drawing Dies Equipment